There are three

sections, namely:

1. Vertical section: It is drilled from sea bed (mud line) until KOP (the point where deviating or sidetracking begins).

2-Turned (Curved or angle-build) section: It is drilled from KOP to the end-of-curve (EOC). This section includes the first-build arc, the straight tangent, the second-build arc.

3. Horizontal section: It is drilled from the end of second-build arc or the end-of-curve (EOC) to the end of the proposed distance to be drilled horizontally in the pay zone, in accordance with the type of the horizontal well to be drilled.

The design of horizontal well based on three method:-1-The simple tangent build curve method:-

The three major sections that form a horizontal well may be designed as follows:-

1-The build-radius of the first-build arc:

R=5730/B

2-Height of the first-build arc:

D1=R(sin I2-sin I1)

3-Height of the straight-tangent:

D2 = L2 Cos I2

4-Height of the second-build arc:

D3=R( Sin I3 - Sin I2).

5-The length of the first section of horizontal well = KOP

KOP = TVD – D1 - D2 - D3

6-The displacement of the first-build arc:

H1 = R ( Cos I1 - Cos I2)

7-The displacement of the straight-tangent:

H2 = L2 - Sin I2

8-The displacement of the second -build arc:

H3= R( Cos I2 - Cos I3)

9-The length of the first-build arc:

L1 =100(I2 - I1 )/B

10-The length of the second-build arc:

L3=100(I3 – I2)/B

11-The measured depth at the end of the first-build arc:

MD1 = KOP + L1

12-The measured depth at the end of the straight tangent:

MD2 = MD 1+ L2

13-The measured depth at the end of the second build arc:

MD3 =MD2 + L3

*The length of the second section =

L1 + L2 + L3 = MD3 - KOP

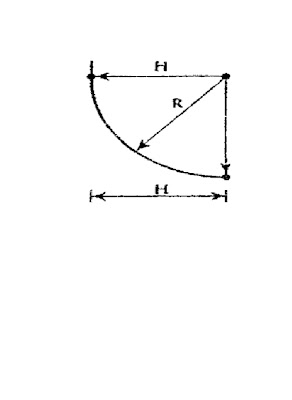

2-circular arc method:-

It is a special design is based where,

R=H=TVDTEP-TVDKOP

Thus. BUR may be determined as follows:

BUR=5730/R

=5730/(TVDTEP-TVDKOP )

Circular arcs are usually drilled only in areas where target entry point (TEP) and directional performance are well known

EX:-the Austin Chalk-amorphous limestone

3-Compound build curve method:-

This method have more than one planned build up rate and one or more tangent sections where, different build up rates will be designed for the upper and lower sections.

EX:-a 4°/100 ft build rate may be used in the

upper section followed by a 8°/100 ft build up rate below the tangent section.

upper section followed by a 8°/100 ft build up rate below the tangent section.

1-Vertical depth of KOP and target selection. This KOP is selected based on hole problems, casing set depths, BHA performance, ROP, . . . etc.

2-Horizontal displacement to target entry point (TEP).

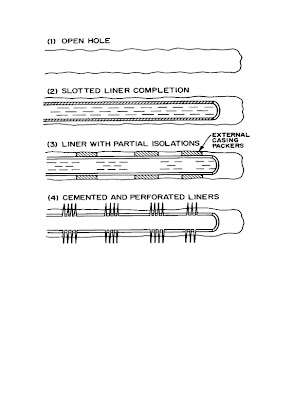

3-Completion design.

4-Formation evaluation program.

5-Hole size in the reservoir.

1-Minimizing hole problems.

2-Minimizing the amount of hole open during directional drilling operations.

3-The planned casing set depths.

4-The performance of directional drilling assemblies within various formations.

5-The expected drilling rate within the various formations.

—

After selecting the optimum KOP, the vertical depth to the target can be determined as mentioned before. This will determine the build radius options available. These options should be refined by considering horizontal displacement to the target entry point (TEP). If the planned profile is compatible with the completion, evaluation program, and desired hole size, the profile selection is complete. If a parameter is not compatible, a design parameter must be altered or compromised, as shown in Table