Types of perforation techniques

2.5.1. According to the relation between

reservoir and hydrostatic pressures

reservoir and hydrostatic pressures

2.5.1.1.

overbalanced

perforation

main features of overbalanced perforation

1-

hydrostatic pressure of fluid in well bore

greater than reservoir pressure

2-

provide control over well while performing

completion

3-

perforation can be plugged with debris in

well bore "difficult in cleaning process"

2.5.2.2.

underbalanced

perforation

main features of underbalanced perforation

1-

Hydrostatic pressure of fluid in well bore

is less than the reservoir pressure

2-

Well is "Live" after perforation

and must be controlled

3-

Perforation will be clean from surge into

well bore

2.5.2.

According to where we do perforation

2.5.2.1.Shop perforated casing are

classified to

- Round perforated

- Slotted perforated

In round perforated casing the diameter

of slots are 1/8 to 3/8 in and it made

by milling or by oxyacetylene torch. The diameter of hole depends on the casing diameter.

by milling or by oxyacetylene torch. The diameter of hole depends on the casing diameter.

In slotted perforation the slots are 0.05 to 0.3 inch wide & 1.5 to

3 inch long and it

also made by milling or by oxyacetylene torch. And we should take care that the total

area of slots equal 2% of casing area. We can also use screen to prevent sand to

enter the well. And we prefer slotted casing than rounded one in sandy formations.

also made by milling or by oxyacetylene torch. And we should take care that the total

area of slots equal 2% of casing area. We can also use screen to prevent sand to

enter the well. And we prefer slotted casing than rounded one in sandy formations.

2.5.2.2. Gun perforated

casing:

The second type of perforation is gun

perforated casing which is our main point

in our study.

in our study.

Optimum

perforation

Perforating is a critical part of any

well completion process .

perforating is the only way to establish conductive tunnels that link oil and gas

reservoirs to steel cased well bores which lead to surface .

however perforating also damage s formation permeability around perforation tunnels .

this damage and perforation parameters like formation penetration hole size ,number

of shots and the angle between holes have a significant impact on pressure

drop near a well ,therefore, on production .optimization the perforation parameter

and mitigating induced damage are the vital aspects of perforating.

Ongoing before perforating is less than the formation pressure is essential

in removing damage and debris from perforations.

perforating is the only way to establish conductive tunnels that link oil and gas

reservoirs to steel cased well bores which lead to surface .

however perforating also damage s formation permeability around perforation tunnels .

this damage and perforation parameters like formation penetration hole size ,number

of shots and the angle between holes have a significant impact on pressure

drop near a well ,therefore, on production .optimization the perforation parameter

and mitigating induced damage are the vital aspects of perforating.

Ongoing before perforating is less than the formation pressure is essential

in removing damage and debris from perforations.

2.5.3.

According to how we do perforation

There are three basic

techniques employed today to perforate a well.

Although the variations are virtually endless, the following discussion

is limited to a basic description of the three techniques. Wells can be perforated

using casing guns conveyed on wire line, through-tubing guns, and

tubing-conveyed guns. Because each method has advantages and limitations,

the completion engineer must choose the most appropriate technique for each well.

Although the variations are virtually endless, the following discussion

is limited to a basic description of the three techniques. Wells can be perforated

using casing guns conveyed on wire line, through-tubing guns, and

tubing-conveyed guns. Because each method has advantages and limitations,

the completion engineer must choose the most appropriate technique for each well.

2.5.2.1. WIRELINE CASING GUN TECHNIQUES

Perforating with a casing

gun conveyed on wire line has been a standard

technique for many years. Before the tubing and wellhead are put in place,

a hollow carrier casing gun is lowered into the well on wire line, positioned

opposite the productive zone, and detonated. The main advantages of this

system are as follows:

technique for many years. Before the tubing and wellhead are put in place,

a hollow carrier casing gun is lowered into the well on wire line, positioned

opposite the productive zone, and detonated. The main advantages of this

system are as follows:

- The diameter of the gun

is limited only by the ID of the casing;

therefore, large, high performance shaped charges can be conveyed

in a multiphase, high shot density carrier.

therefore, large, high performance shaped charges can be conveyed

in a multiphase, high shot density carrier.

- The casing gun offers

high reliability because the blasting cap

detonating cord and shaped charges are protected from the wellbore

environment and the carrier is mechanically strong.

detonating cord and shaped charges are protected from the wellbore

environment and the carrier is mechanically strong.

- Selective firing is

available between guns.

- Guns are accurately

positioned opposite the zone of interest using

a casing collar locator.

a casing collar locator.

- No damage occurs to the

casing and virtually no debris is left

in the well.

in the well.

There are two main limitations to this method:

- As a general practice, the well must be perforated with

the wellbore pressure

greater than the formation pressure. This pressure differential may prevent

optimum cleanup of the perforations. The situation is aggravated when perforating in

drilling mud. The mud plugs are difficult to remove even when subjected to high

reverse pressure. Perforating in clean liquids such as salt water is recommended.

greater than the formation pressure. This pressure differential may prevent

optimum cleanup of the perforations. The situation is aggravated when perforating in

drilling mud. The mud plugs are difficult to remove even when subjected to high

reverse pressure. Perforating in clean liquids such as salt water is recommended.

- The strength of the wireline and the weight of the casing

guns limit the length

of the assembly which can be run on each trip into the well.

of the assembly which can be run on each trip into the well.

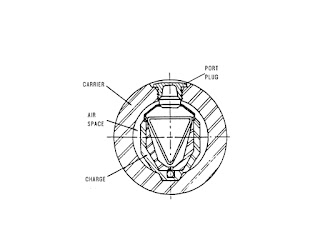

There are three basic types of casing guns:

1. Port Plug Guns

2. Scalloped Guns

3. Slick Walled Guns

Each gun design has the same primary purpose to seal the

guns from the wellbore

pressure and fluids. The differences are in how this is achieved and how the

individual charges are secured in place. Port Plug guns are re-usable carriers

that use the port plug to secure the charge (Figures B17 and B18). The perforating

charge has to penetrate the carrier before it can perforate the casing. Port Plug guns

are designed so that the charge perforates a port plug which can be replaced and the

gun re-used. Gun life is not indefinite but being able to distribute the carrier cost

over 10 to 15 jobs reduces the overall cost of perforating. Fig. B18: Port Plug Gun.

pressure and fluids. The differences are in how this is achieved and how the

individual charges are secured in place. Port Plug guns are re-usable carriers

that use the port plug to secure the charge (Figures B17 and B18). The perforating

charge has to penetrate the carrier before it can perforate the casing. Port Plug guns

are designed so that the charge perforates a port plug which can be replaced and the

gun re-used. Gun life is not indefinite but being able to distribute the carrier cost

over 10 to 15 jobs reduces the overall cost of perforating. Fig. B18: Port Plug Gun.

Scalloped guns are

typically used when high shot density perforating

(greater than 4 spf, 13 spm) is required. The carrier is a metal tube

with Flat bottomed holes milled on the outside, about 3 mm deep. These

scallops are aligned with the perforating charges inside the gun so that the

charges fire through the centre of the scallop. This does not significantly

change the penetration of the charge but rather is to ensure

(greater than 4 spf, 13 spm) is required. The carrier is a metal tube

with Flat bottomed holes milled on the outside, about 3 mm deep. These

scallops are aligned with the perforating charges inside the gun so that the

charges fire through the centre of the scallop. This does not significantly

change the penetration of the charge but rather is to ensure

that any burring that may have occurred on the gun wall does

not exceed

the overall gun outside diameter.

the overall gun outside diameter.

The charges are held in place by a tube or triangular strip

(Figure B19)

which is slid into the gun itself. The scalloped gun is used for high shot

density because the cost of machining so many port plug holes (up to 39 per meter)

is prohibitive and the chance of a port plug leaking and flooding the guns is obviously

increased. Another common use for the scalloped carrier is for TCP work.

Whenever a TCP system is used for a permanent completion, the guns will

not be retrieved, for this case the cost of machining port plugs will not be

recovered. Fig. B20: Slick Walled Gun.

which is slid into the gun itself. The scalloped gun is used for high shot

density because the cost of machining so many port plug holes (up to 39 per meter)

is prohibitive and the chance of a port plug leaking and flooding the guns is obviously

increased. Another common use for the scalloped carrier is for TCP work.

Whenever a TCP system is used for a permanent completion, the guns will

not be retrieved, for this case the cost of machining port plugs will not be

recovered. Fig. B20: Slick Walled Gun.

The Slick Walled guns are

a unique carrier designed for a moderate environment (Figure B20).

The gun carriers have neither port plugs nor scallops. It is simply smooth surfaced

pipe through which the charges perforate. This causes some burrs on the outside

of the carrier but as long as enough clearance exists no problems will be encountered.

The carrier and explosives are rated for lower pressures and temperatures than

other gun systems (27.5 MPa, 99 degree C for 1 hour) and can only be loaded to

a maximum of 13 spm (4 spf). The charges are held in place by a moulded Styrofoam

case which allows quick efficient loading.

The system allows for cost effective perforating of shallow to medium (2500 m) depth wells

The gun carriers have neither port plugs nor scallops. It is simply smooth surfaced

pipe through which the charges perforate. This causes some burrs on the outside

of the carrier but as long as enough clearance exists no problems will be encountered.

The carrier and explosives are rated for lower pressures and temperatures than

other gun systems (27.5 MPa, 99 degree C for 1 hour) and can only be loaded to

a maximum of 13 spm (4 spf). The charges are held in place by a moulded Styrofoam

case which allows quick efficient loading.

The system allows for cost effective perforating of shallow to medium (2500 m) depth wells

2.5.2.2. THROUGH-TUBING PERFORATING TECHNIQUE

In 1953, Humble Oil and Refining Co. pioneered

the permanent-type well completion.

This technique involves setting the production

tubing and wellhead in place and

then perforating the well with small diameter guns capable of running through tubing.

The main advantages of this technique are as follows:

then perforating the well with small diameter guns capable of running through tubing.

The main advantages of this technique are as follows:

- The well may be perforated with the wellbore

pressure below the formation pressure

allowing the reservoir fluids to instantly clean up the perforating debris.

allowing the reservoir fluids to instantly clean up the perforating debris.

- Completion of a new zone or a workover of an

existing zone does not require

the use of a rig.

the use of a rig.

- A casing collar locator allows for accurate

depth positioning.

The main limitations of this method are as

follows:

- To allow the gun to run through tubing,

smaller shaped charges, with reduced

penetrations, must be used. To achieve maximum penetration with through tubing

perforators the gun is usually positioned against the casing to eliminate the loss

of performance when perforating through the liquid in the wellbore.

This arrangement restricts the gun to 0o phasing.

penetrations, must be used. To achieve maximum penetration with through tubing

perforators the gun is usually positioned against the casing to eliminate the loss

of performance when perforating through the liquid in the wellbore.

This arrangement restricts the gun to 0o phasing.

- In an effort to improve the penetration

performance, gun system designers

eliminate the hollow steel carrier and place pressure tight capsule charges

on a strip or wire. These guns are called expendable or semi-expendable

depending on whether the wire or strip is retrieved. Removing the steel

carrier allows a larger charge to be used; however, charge case

debris is left in the well after perforating and the casing may be

damaged by the detonation.

eliminate the hollow steel carrier and place pressure tight capsule charges

on a strip or wire. These guns are called expendable or semi-expendable

depending on whether the wire or strip is retrieved. Removing the steel

carrier allows a larger charge to be used; however, charge case

debris is left in the well after perforating and the casing may be

damaged by the detonation.

- The charges are exposed in the expendable and

semi-expendable systems restricting

these guns to less severe well environments and lower running speeds.

these guns to less severe well environments and lower running speeds.

As stated earlier, these guns, designed to pass

through tubing are used for a variety of reasons:

1. Critical sour gas wells where a permanent

packer is to be in place before perforating occurs.

2. Older wells where a retrievable packer cannot

be un-set due to failure.

3. Perforate slim casings or liners (89 mm).

.

The small outside diameter of through-tubing guns implies

that if the charges are to

be contained inside of a tube (HSC) the explosive load will have to be small. Such

is the case with our hyper dome guns (Figure B21). With explosive weights of

1.8 gm to 6.5 gm, penetrations can be limited but exposure to wellbore fluids

and potential failure thereby is eliminated. Fig. B22: Enerjet Gun.

be contained inside of a tube (HSC) the explosive load will have to be small. Such

is the case with our hyper dome guns (Figure B21). With explosive weights of

1.8 gm to 6.5 gm, penetrations can be limited but exposure to wellbore fluids

and potential failure thereby is eliminated. Fig. B22: Enerjet Gun.

If deeper penetration is required, an expendable or

semi-expendable carrier is required.

Because the gun outside diameter is governed by the charge size, a maximum load can

be placed down hole after passing through the tubing. Care must be taken not to attempt

too large of an explosive charge. If unenclosed charges in excess of 20 grams are

allowed to detonate downhole, casing damage could result.

Because the gun outside diameter is governed by the charge size, a maximum load can

be placed down hole after passing through the tubing. Care must be taken not to attempt

too large of an explosive charge. If unenclosed charges in excess of 20 grams are

allowed to detonate downhole, casing damage could result.

Typical of these carriers is our Enerjet gun where the

charges are threaded into

a steel bar (Figure B22). Explosive loads can go as high as 15.5 gms and after

detonation the steel bar and threaded caps are retrieved from the well.

In this manner only a minimum amount of debris, in the form of powder is left behind.

a steel bar (Figure B22). Explosive loads can go as high as 15.5 gms and after

detonation the steel bar and threaded caps are retrieved from the well.

In this manner only a minimum amount of debris, in the form of powder is left behind.

2.5.2TUBING-CONVEYED PERFORATING

TECHNIQUE

TECHNIQUE

Although various attempts were made to convey perforating

guns into

the well on tubing it was not until the early 1980's that widespread use

of the service began. The basic technique involves assembling hollow

carrier steel casing guns vertically with a firing head on top. There

are several types of firing heads including drop bar, differential pressure,

direct pressure, and electrical wet connect. On top of the firing head

is a sub used to allow reservoir fluids to flow into the tubing.

A production packer is attached above the fluid communication sub.

This entire assembly is then lowered into the well on the end of the tubing string.

The string is depth positioned usually with a gamma ray survey.

After the guns are positioned,

the packer is set, and the well is readied for production.

This includes establishing the correct underbalanced condition in the tubing.

The guns are then fired and the surge of reservoir fluids is used to clean

up the perforations. Depending on the situation the guns may be retrieved or dropped to the bottom of the well.

Many variations of the procedure described above are in use today.

The main advantages of this technique are as follows:

the well on tubing it was not until the early 1980's that widespread use

of the service began. The basic technique involves assembling hollow

carrier steel casing guns vertically with a firing head on top. There

are several types of firing heads including drop bar, differential pressure,

direct pressure, and electrical wet connect. On top of the firing head

is a sub used to allow reservoir fluids to flow into the tubing.

A production packer is attached above the fluid communication sub.

This entire assembly is then lowered into the well on the end of the tubing string.

The string is depth positioned usually with a gamma ray survey.

After the guns are positioned,

the packer is set, and the well is readied for production.

This includes establishing the correct underbalanced condition in the tubing.

The guns are then fired and the surge of reservoir fluids is used to clean

up the perforations. Depending on the situation the guns may be retrieved or dropped to the bottom of the well.

Many variations of the procedure described above are in use today.

The main advantages of this technique are as follows:

- The well can be perforated with large diameter, high

performance;

high shot density casing guns with the wellbore pressure lower

than the formation pressure (underbalanced) allowing instantaneous cleanup of the perforations.

high shot density casing guns with the wellbore pressure lower

than the formation pressure (underbalanced) allowing instantaneous cleanup of the perforations.

- The wellhead is in place and the packer is set before the

guns are fired.

- Large intervals can be perforated simultaneously on one

trip into the well.

- Highly deviated and horizontal wells can be perforated by

pushing the guns into the well.

The main limitations of the technique are as follows:

- Unless the guns are withdrawn from the well it is

difficult to confirm whether the entire

gun fired. Effective shot detection systems may overcome this limitation.

gun fired. Effective shot detection systems may overcome this limitation.

- Explosives degrade when exposed to elevated temperatures,

reducing shaped charge performance. It takes many times longer to run a TCP string into the hole than a wire line gun. To compensate, a more expensive and, in some cases, less powerful explosive must be used on TCP operations.

reducing shaped charge performance. It takes many times longer to run a TCP string into the hole than a wire line gun. To compensate, a more expensive and, in some cases, less powerful explosive must be used on TCP operations.

- Selective perforating options with TCP are limited. Small

intervals over large intervals may not be economical with TCP.

- Accurate depth positioning of the gun string is more

difficult and time consuming than wire line depth positioning.

2.5.2.3.1. TCP FIRING SYSTEMS

Several firing techniques are available for various types of

completion or testing operations. They include percussion, pressure, and

electrically activated systems.

2.5.2.3.2. Percussion-Activated Firing

Head (Drop-bar)

The drop bar is the simplest TCP firing system. A

cylindrical weight or sinker bar is dropped into the tubing and strikes a

percussion- type detonator in the gun firing head.

Hydraulic pressure on the tubing fluid column is adjusted to

achieve the desired underbalance on the formation before dropping the bar. The

bar can be dropped by hand through an open wellhead control valve or contained

in a wireline lubricator and released when wellhead valves are opened and can

also be run on a slickline.

2.5.2.3.3. Bar Actuated Pressure Firing

System

The gun is not fired by the impact of the drop bar on the

firing head. Instead, the drop bar shears a pin, which releases the catch on

the firing piston. The firing piston is then driven hydrostatically towards the

percussion cap to set off the detonating train. A minimum hydrostatic head of

500 psi is needed in the tubing to set the gun off. With this feature, it is

not possible to accidentally fire the gun at surface by dropping anything on

the firing head. If the well is perforated dry, the 500 psi required can be

obtained by pressuring the tubing with nitrogen prior to dropping the bar.

2.5.2.3.4. Differential-Pressure Firing Head

The differential-pressure firing head utilizes a flowtube

through the packer to transfer annulus pressure above the packer to an isolated

piston in the firing head located beneath the packer. The advantage of this

firing method is that, after setting the packer, the tubing and packer can be

tested in the direction of well pressure by internally pressuring the tubing

and transmitting this pressure to casing beneath. After Pressure testing, the

desired underbalance pressure is fixed before firing the guns. The annulus

pressure forces the release piston downward, breaking the shear pins and releasing

the locking lugs which secure the firing pin. The hydrostatic pressure in the

rathole below the packer then drives the firing pin into the percussion cap,

igniting the Primacord which fires the perforating guns.

2.5.2.3.5. Tubing - Pressure Firing System

This system uses a percussion-activated firing head similar

in principle to the differential pressure and drop-bar systems, except that it

is activated by internally pressuring the tubing. This same system is used,

without modification, for DST’s or permanent completions. After setting the

packer, it is tested by pressuring the tubing annulus. Next, the tubing

pressure is raised through three specific pressure cycles to arm the gun. Two

of these are redundant safety cycles built into the system to account for

unanticipated excursions such as high pressure surges, swab pressures, and high

circulating pressures. After the three cycle sequence, there is a variable time

delay before firing in order to correct underbalanced pressure and adjust

wellhead choke manifolds.

An advantage of the tubing-pressure system is that it can be

fired in wells where the casing above the packer is leaking; e.g., split or

corroded pipe and old squeeze perforations.

2.5.2.3.6. Electric - Wire line Firing

System

The electric-wire line firing system uses electric current

and logging cable for firing. Conventional wire line pressure-control equipment

(lubricator, blowout preventer, etc.) is used during flow testing with cable in

the hole. The wet connector contains a mechanical latch that secures it to the

TCP firing head, preventing the cable from being blown uphole. With these

firing systems, an electric current transmitted to a wet connector at the gun

head fires the detonator. One of the major advantages of these systems is that

they cannot be inadvertently armed and fired before the electric power source

is connected with the firing head. A gamma ray and collar log can be run with

the electric-wire line firing system.

Personnel safety is one of our highest concerns;

Schlumberger requires the use of a minimum three meter safety spacer above the

gun. This ensures that the guns are below the rig floor when the firing head is

connected. Cleanliness is the most important factor governing success or

failure of a TCP operation. A dirty workstring with pipe scale, dope, or gelled

mud with high solids content can prevent access to any of the firing head

systems. Any workstring (new or used) should always be rattled or washed clean

before picking up the TCP assembly. Pipe dope should be used sparingly. Once on

bottom, circulation should be established to flush trash through the

circulating sub. A joint of tubing filled with clean fluid should be run

immediately below the circulating sub. If the TCP assembly contains a closed

annular production valve and the workstring is filled on the floor with clean

brine or diesel while going in hole, circulation is not necessary. In

high-angle holes the drop bar should not be used, and pressure-type firing

systems are recommended. Gun release subs should be used with permanent

completions to allow production logging and access to perforations for remedial

stimulation work. If sufficient casing rathole is not available to accommodate

the fired guns, they can be pulled out of the well if a stabthrough TCP

arrangement is used with a larger bore packer. However, this is not desirable

since the well will have to be killed and equipment pulled and rerun. Such a

system would likely require guns with smaller OD’s. The optimum underbalance

pressure is dependent upon several factors such as perforation size and length,

rock strength, reservoir permeability, and fluid viscosity. All of these, in

theory, affect the ability of the perforation to be cleaned. As a practical

matter, the underbalance pressure should be between a minimum of a few hundred

pounds per square inch and a maximum of the design collapse rating for the

casing. Low-permeability formations and zones producing gas require larger

pressure differentials to clean up the perforations.

Some of the most

common TCP accessories are listed on the following pages.

2.5.2.3.7.1. Radioactive

Marker Sub

The sub is run in line with the workstring above

the packer, or can simply be a tubing collar or a drill pipe tool joint where

one or two small cavities have been drilled and threaded to receive a sealing

plug. A radioactive pip tag is installed in each cavity. A pip tag is a

very weak gamma ray source (1 microcurie of Cobalt 60). The radiocative marker

sub is run above the packer, and all the radioactive material is fully

recovered when the string is pulled (Figure B23).

2.5.2.3.7.2.Cone-Type

Debris Circulating Sub

The debris circulating sub (Figure B24) consists

of a ceramic cone seated into a ported sub. The sub is positioned between the

packer and the guns, typically 10 m above the firing head. The isolated space

below the sub is filled with a clean fluid. Once the assembly above the sub has

been circulated clean, the packer is set. A debris circulating sub is often

used with a drop bar or a wet connected firing system to prevent debris from

settling on the downhole portion of the firing head. The drop

bar or female wet connector will easily break

the fragile cone to reach the firing head.

2.5.2.3.7.3.Mechanical Gun

Release Sub

The operating principle of the mechanical gun

release sub (Figure B25) is similar to other gun release subs. After a release

sleeve is shifted, the lower sub locking fingers retract. The lower sub and the

gun string are then released and fall to the bottom of the well. Fig. B25:

Gun Release Sub. Fig. B26: Surge-Disc Sub

2.5.2.3.7.4. Surge-Disc Sub

The surge-disc sub (Figure B26) features a

fragile, high strength, sealed, glass disc inside a sub. The disc is designed

to withstand a high differential pressure.

The sub is positioned above the circulating sub,

completely sealing off the portion of tubing above it. This portion of tubing

can be dry or partially filled with a clean fluid cushion to create an

underbalance condition after the packer is set and the disc broken. In the

presence of old perforations, the sub can be used with a drop bar firing

system. In this application, the underbalance will be established a few seconds

before firing the guns. The underbalance will remain effective during

firing and at the time of the surge immediately after firing.

2.5.2.4. COILED TUBING CONVEYED PERFORATING FOR HORIZONTAL WELLS

2.5.2.4.1. Principle

The principle of this system (Figure B27) is

particularly simple: the guns are mounted directly on the end of tubing coiled

on a reel in which the electric cable has first been inserted. The connection

between guns and tubing ensures the mechanical and electrical bottom link,

while on the surface; the cable outlet passes through the shaft of the drum by

a rotating device. The lowering and raising movements are provided by the standard

coiled-tubing injector head, and the depth measurements are made on the tubing

near the injector. This technique is equally capable of conveying

small-diameter guns and standard guns, but the performance capabilities will be

affected by gun weight. In addition, circulation through the coiled tubing

remains available, although the cross section is reduced, owing to the cable.

2.5.2.4.2. Procedure

The logging procedure with this system is

exactly the same as that for normal use of coiled tubing. Should it be

necessary to work under pressure, a lubricator adapted to the guns should be

added. The weak link in this system is its relative fragility, rendering it

incapable for pushing heavy guns over great distances. Fig. B28:

Perforating Depth Control.