the completion that can be run through a given

radius of curvature will depend on

1.the radial clearance between the

completion item and hole(liner size),

2. the length and flexibility of the completion,

3.the rating of the connection

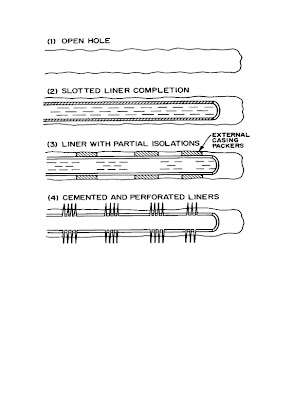

Horizontal well Completion Options

1.Open hole 25%

2.Slotted

Liner 55%

3.Liner

with Partial Isolations 15%

4.Cemented

and Perforated Liners 5%

Open hole 25%

1.This type of completion is the simplest and cheapest typed used in consolidated

& competent reservoir Rock with almost no sand

production.

2.It is represented 25% from total or all completions worldwide

1.It is used with or without a screen

2.It is used when the reservoir is unconsolidated or loosely consolidated sands.

3.It is formed 55% from all completions worldwide and it is considered as a

prevailing well completion type.

4.its main purpose

—to guard against hole collapse

—to provides a convenient path to insert various tools such as

coiled tubing in a horizontal well

●

Liner with Partial Isolations 15%

—Slotted

liner in open hole with blank sections and External Casing Packer

(ECP).

—This is 15% of total

completions worldwide.

—

Cemented and Perforated Liners 5%

—It is expensive and used

in long-radius horizontal sections or for medium-radius horizontal

sections. It is formed only 5% of all

completions worldwide.

—Problems

like difficulty of cement job or leakage of

cement sheath may arise in this type